The USDA Choice and USDA Prime grade shields are highly regarded, both domestically and internationally, as symbols of high-quality American beef. Cattle producers and feeders increasingly rely on USDA grades to determine payments for their cattle—a vital link to supporting and sustaining rural America.

Beef is graded at about 35 facilities nationwide, with some facilities handling over 5,800 cattle per day, for a combined total of about 26 million fed steers and heifers annually. Historically, beef was evaluated by highly-skilled USDA meat graders using a mostly subjective characteristic assessment process.

These characteristics follow the official grade standards developed, maintained and interpreted by the USDA’s Agricultural Marketing Service. However, years of research and development have led to recent innovations that improved the precision of USDA’s beef grading system—the use of electronic instruments to assess meat characteristics.

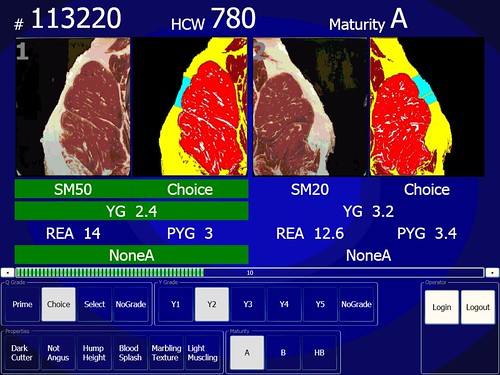

Implemented on September 1, 2009, the electronic instrument grade augmentation system captures images on camera, which are then analyzed by a computer program. This has contributed to an increasingly uniform application of the official grade standards on a nationwide basis.

Grading instruments can only predict or measure some of the specific attributes necessary for a final grade. And, although instrument grading does change some of USDA’s traditional grading activities, it is not a replacement for on-site staff and does not eliminate the need for highly-trained and skilled employees.

Just like a plane flying on “auto- pilot” requires human oversight, USDA still maintains a human presence in the facility to ensure the correct equipment and cameras are used and that they are operating as intended. USDA meat graders also provide in-plant, day-to-day, item-by-item supervision to verify the accuracy of the electronic system and proper instrument operation.

Since the entire marketing chain relies on USDA’s beef grading program, all parties—from producers to consumers—must have a high-degree of confidence in the integrity of the system and accuracy of the applied grades. By using new technology to enhance our grading process and continuing to leverage the expertise of our graders, the USDA grade shield is backed by rigorous expert evaluation, strict grading criteria and an even more impartial judge.