Hitting your target—and only your target—is a top priority when spraying pesticides from an airplane. And the use of a small object could be a big help in making sure that happens.

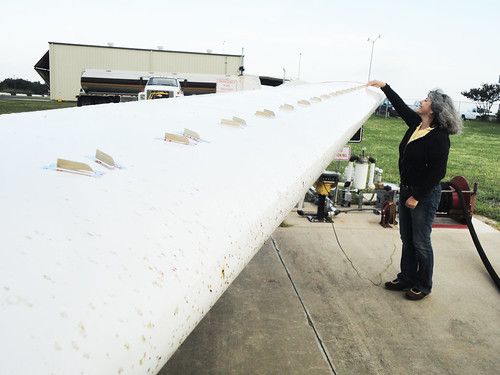

That’s the focus of the research being conducted by Daniel Martin, an engineer with Agricultural Research Service’s (ARS) Aerial Application Technology Research Unit in College Station, Texas. Martin has shown that attaching dime-sized metal clips to airplane wings—a technology known as “vortex generators”—can reduce pesticide drift.

Vortex generators (VGs) are common on commercial airliners as well as on smaller aircraft to provide pilots better control of the aircraft. Now, thanks to Martin and others, VGs are reducing the drift of pesticides sprayed by agricultural aircraft.

“It’s a matter of aerodynamics,” Martin says. An airplane gets lift from an area of high pressure passing under the wings and an area of low pressure passing over them. But as air passes over and under the wings, it moves up and around them in chaotic whirlwind patterns, particularly at the wing tips. VGs are T-shaped, and when they are attached to the edge of the wing, each one becomes a focal point (a vortex) that stabilizes the flow of air as it passes over and under the wing.

On most agricultural aircraft, the spray nozzles are attached to booms that hang below the wings. VGs make for a smoother and more controlled flow of air below the wing near those nozzles. “VGs channel the air flow and concentrate it so that it pushes the spray down towards the crop canopy,” Martin says. VGs also are often attached to the plane’s rear stabilizer to produce the same beneficial effect. The overall effect is less pesticide drifting off target.

Martin started evaluating VGs a few years ago in an effort to reduce spray drift. He and his colleagues sprayed a target field near College Station to measure drift and deposition rates of a test spray released from a plane. They placed moisture-sensitive cards at various distances outside the target to measure downwind deposits.

The results showed that the type of clips used in the study, Micro VGs, produced by Micro Aerodynamics, Inc. of Anacortes, Washington, dramatically reduced downwind deposits and drift.

Martin plans to publish his findings soon and is planning future flights and studies with an eye toward finding ways to maximize the technology’s benefits. In the meantime, word is quickly getting out, and some aircraft manufacturers now include VGs on their latest aircraft not only to provide better control of the aircraft but also to mitigate drift. Agricultural aviation supply companies sell VG kits that can be installed on small planes in just a few hours.

“Drift is a huge issue when it comes to aerial spray application, and from what we have seen, this technology could not only help reduce drift into unwanted areas, but it could also help growers save on pesticide costs by ensuring that more of the pesticides reach their target,” Martin says.

USDA has invested $19 billion in research and development since 2009, touching the lives of all Americans from farms to the kitchen table and from the air we breathe to the energy that powers our country. Learn more about the many ways USDA scientists are on the cutting edge, helping to protect, secure and improve our food, agricultural and natural resources systems in USDA’s Medium Chapter 11: Food and Ag Science Will Shape Our Future.