The U.S. Geological Survey estimates that several million earthquakes occur in the world each year. Some, such as the devastating earthquake in Nepal and the series of earthquakes that destroyed infrastructure, homes and communities in Christchurch, New Zealand in 2011, capture global attention.

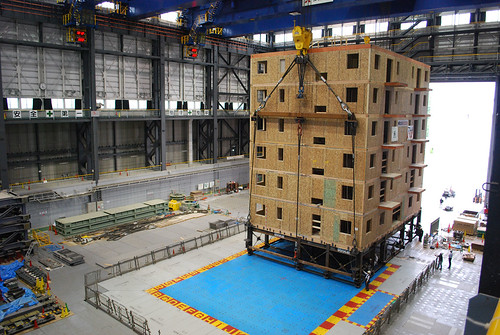

After natural disasters such as these, rebuilding a city needs to be efficient and cost-effective, with an eye towards resilience in the face of future disasters. Engineered wood building systems like glulam and cross laminated timber, also known as CLT, are well suited to meet these needs as they are often prefabricated offsite and can be quickly installed. That helps communities bounce back from disaster in a shorter time frame while minimizing waste. Furthermore, just as trees flex in high winds, timber structures flex in earthquakes, placing wood construction systems at the forefront of seismic design for resilience.

CLT is relatively new to North America, having first gained popularity in Europe. CLT panels are typically constructed by laminating three or more layers of lumber together, with each layer perpendicular to the neighboring layer to create a solid wood panel. These panels are a renewable building material that is strong and versatile, and utilize smaller wood elements from sustainably managed forests.

Many of our nation’s forests have become overstocked as a result of past fire suppression policies. Today, the U.S. Forest Service is working with partners to remove small diameter trees, restoring the density and composition of our forests to better support natural fire regimes and provide benefits that we rely on, including clean water, wildlife habitat, and recreational opportunities. Using the byproducts of these restoration treatments creates viable markets for smaller trees, decreasing the cost of forest restoration treatments and creating jobs in rural and urban areas along each stage of the supply chain.

To promote the adoption of innovative wood building technologies, the U.S. Department of Agriculture is sponsoring the U.S. Tall Wood Building Prize Competition in partnership with the Softwood Lumber Board and the Binational Softwood Lumber Council. This competition showcases the architectural and commercial viability of advanced wood products in tall-building construction, growing this emerging market and ultimately supporting employment opportunities in rural communities, maintaining the health and resiliency of U.S. forests, and advancing sustainability in the built environment.

Additionally, USDA is working to stimulate demand for forest products and expand the use of wood in building through research into innovative ways to use wood and fiber. The U.S. Forest Service Forest Products Laboratory, based in Madison, Wisconsin, has been an integral part of developing safe and sustainable products, including different applications for engineered wood products like CLT. Part of Forest Service Research & Development, the FPL has invested over $2 million in research and technical support for the use of wood as a green building material for housing developments and other building projects.

One facet of this research, spearheaded by FPL researcher Bob Falk, is looking to enhance human safety in the face of tornados. Each year in the U.S., tornadoes results in more than 80 deaths and 1,500 injuries. Through the development of a “Do-It-Yourself” tornado safe room that can be constructed by anyone with basic construction skills using innovative wood products, the research has the potential to greatly reduce casualties associated with these natural disasters.

In early April, Secretary Tom Vilsack announced the award of over $9 million awarded to expand and accelerate wood energy and other wood product markets. These federal funds will leverage $22 million in investments from partners, resulting in a total investment of $31 million in 23 states.

This post is part of a series featuring the Forest Service’s work on restoration across the country.