It’s no secret that Americans eat a lot of chicken and turkey. In fact, USDA estimates that a single American will eat 102 pounds of poultry in 2015. It is USDA’s job to ensure the meat and poultry products we enjoy are also safe to eat, and that means adapting federal food safety regulations to meet changes in production technology, scientific understanding of foodborne illness, and consumer demand.

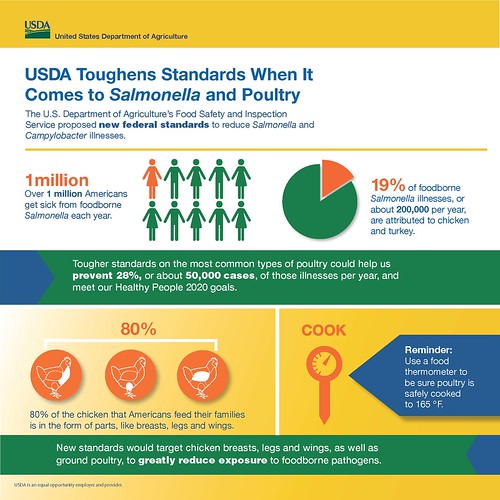

According to the Centers for Disease Control and Prevention, over 1 million Americans contract foodborne Salmonella poisoning each year, and 200,000 of those illnesses can be attributed to poultry. Today, USDA’s Food Safety and Inspection Service proposed new food safety standards that would reduce Salmonella and Campylobacter, another common cause of foodborne illness, on ground chicken and turkey, as well as chicken legs, breasts and wings, which represent the majority of poultry items that Americans purchase and feed their families.

By taking specific aim at lowering contamination on these products, an estimated 50,000 cases of foodborne illness could be averted annually.

Since 1996, FSIS has used pathogen reduction performance standards to measure the food safety performance of meat and poultry businesses. With this proposal, FSIS would make the performance standards for ground poultry tougher to meet, which would reduce Salmonella and Campylobacter levels on ground poultry nationwide. FSIS implemented performance standards for whole chickens in 1996 but has since learned that Salmonella contamination levels increase as chicken is further processed into parts. By creating a first-time-ever standard for chicken parts, and by performing regulatory testing at a point closer to the final product, FSIS can greatly reduce consumer exposure to Salmonella and Campylobacter.

In addition, FSIS is proposing to be more strategic in the way we schedule microbial tests for Salmonella and Campylobacter at poultry facilities so we can gain a better picture of the food safety realities from business to business. Currently, we schedule a “set” of 52 samples at a facility, which are taken on consecutive days once the set is started. Facilities are categorized according to the number of samples that test positive in their set. Some retailers will only purchase chicken from the top category, so companies are motivated to be among those performers who meet or do better than the national performance standard. By stretching a sample set out over the course of a year so that samples are not collected on consecutive days, and by not alerting the company that the sample will be collected, results will be less affected by intermittent seasonal or production changes, and it will take longer for a company to move from a lower to a higher category. This should prompt companies to take meaningful steps that have a long lasting impact on the safety of their products.

The steps we are proposing are major pieces of FSIS’ Salmonella Action Plan, which the agency developed and released in 2013 to reduce Salmonella illnesses from meat, beef and pork. Collectively, these three foods contribute to about one third of all Salmonella illnesses, and FSIS aims to significantly reduce that number to meet the U.S. government’s Healthy People 2020 goals.