With a little help from USDA, consumer-grade photo scanners could revolutionize rice grading.

Consumers much prefer whole kernels of milled rice over broken pieces. Whole kernels offer more consistent cooking qualities and are in many cases considered more visually appealing. As a result, the price paid to a rice producer for a load of rough rice can be impacted by the percentage of broken kernels within a sample of rice after it has been milled.

USDA’s Grain Inspection, Packers and Stockyards Administration is developing software for use with consumer-grade photo scanners to measure the percent of broken kernels in milled rice quickly and accurately. When rough rice is graded in accordance with USDA’s Rice Grading Standards, the percentage of broken kernels within a sample is determined by a trained grader’s visual inspection.

Mechanical sizing equipment instead of visual inspection is routinely used for separating whole and broken rice pieces at various points of the rice marketing process to save time and cost, but mechanical sizing doesn’t account for inherent differences in rice kernel size.

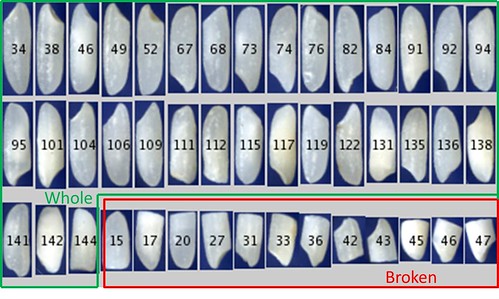

USDA’s Rice Studio software rapidly analyzes images of milled rice from a flat-bed scanner. It identifies fully intact kernels, and then precisely compares fractured kernels with the most similar fully intact kernels to determine whether each fractured kernel is whole or broken. The program then computes the percentage of broken kernels by weight. The entire process requires less than five minutes.

The Rice Studio is designed to operate with a wide variety of computers and flatbed photo scanners. When it is complete, GIPSA will be making this technology available to all interested users.